Basic information of the workshop:

The company currently has two production workshops: 1. Comprehensive workshop (including: workshop one for oral solid preparations, workshop two for traditional Chinese medicine extraction (workshops one and two are currently in a state of shutdown), workshop three for small capacity injection, workshop six for glass bottle infusion, and workshop seven for multi-layer co extrusion infusion bags infusion), which undertake the production of various entrusted products year-round, At present, more than 30 specifications of 20 products have been entrusted for production cooperation agreements with 12 drug market licensors. 2. Workshop Five is a plastic bottle infusion workshop that produces polypropylene infusion bags and upright polypropylene infusion bags year-round.

1. Comprehensive workshop

(1) Three workshops (small capacity injection workshop): with a building area of approximately 3091 square meters, there are currently two production lines, including final sterilization process and non final sterilization process production lines, which can produce 1mL to 20mL packaging specifications of products; Annual production capacity: 300 million small volume injections; The products produced year-round include metronidazole injection, arginine hydrochloride injection, ribavirin injection, vitamin B6 injection, etc.

.jpg)

(2) Six workshops (glass bottle production workshop): with a building area of approximately 2464 square meters, there is a production line that can produce 50mL, 100mL, 250mL, and 500mL; Capable of producing 120 million bottles of glass bottle products annually. Products produced year-round: compound amino acid injection, mannitol injection, tinidazole sodium chloride injection, etc.

.jpg)

(3) Seven workshops (multi-layer co extrusion infusion bag workshop): with a building area of approximately 3378 square meters and a purification area of 679 square meters, there is a production line that can produce packaging specifications of 50mL, 100mL, 250mL, 500mL, and 1000mL; Annual production capacity: 120 million soft bags. Products produced year-round: Basic infusion.

.jpg)

2. Workshop Five Plastic Bottle Production Workshop

The building area is approximately 10956 square meters, with a purification area of 1926 square meters. There are two production lines: A line (250mL, 500mL) and B line (50mL, 100mL), with a production capacity of 120 million polypropylene infusion bottles; 40 million upright polypropylene infusion bags. Products produced year-round: basic infusion, levofloxacin lactate sodium chloride injection, metronidazole sodium chloride injection, etc.

.jpg)

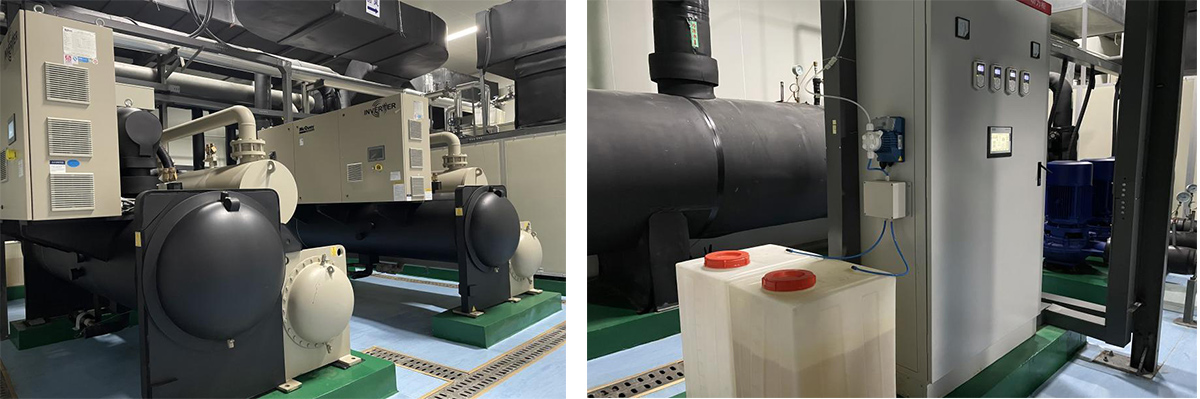

2. Air conditioning system

The Company has a total of 13 sets of air conditioning systems. There are two air conditioning units in workshop one, one in workshop two, three in workshop three, four in workshop five, one in workshop six, and two in workshop seven. Air conditioning system: The air conditioning purification system adopts a combination air conditioning box and a supply and return air system. The fresh air and return air are mixed and sent to the clean area through primary efficiency filters, medium efficiency filters, and high-efficiency filters. The cleanliness level of high-capacity injection production is C level and local A level under the background of C level, the cleanliness level of the final sterilization process production line for small capacity injection is D level, C level and local A level under the background of C level (sealing process), and the cleanliness level of the non final sterilization process production line is D level, C level, B level and local A level under the background of B level (sealing process).

3 Process water system

The company currently has two sets of process water systems (including purified water and injection water systems). The purified water system in System I (Workshop 5) has a water production capacity of 20T/hour, and two multi effect injection water systems with a capacity of 12T/hour.

The purified water system of System II (Workshop 6) has a water production capacity of 40T/h, with 3 multi effect injection water units at 18T/h.

Water production system 1 meets the production needs of the company's first, fifth, and seventh workshops, while water production system 2 meets the production needs of the company's second, third, and sixth workshops.

The injection water adopts a thermal insulation cycle above 70 ℃, the storage tank and pipeline system are regularly cleaned, and pure steam sterilization is used.

4.Warehouse Center

The total construction area of the warehouse is 27980m2, with three storage areas. Among them, the first storage area is 20133m2, adjacent to the plastic bottle production line, mainly involving the raw material warehouse (a total of 1530 m2, including 1110m2 of normal temperature warehouse and 420m2 of cool warehouse), packaging material warehouse (265m2 of inner packaging material warehouse, 1311m2 of outer packaging material warehouse, 62m2 of printing packaging material warehouse), non-conforming product warehouse (50m2), return warehouse (99 m2), normal temperature finished product warehouse (16295m2), and cool finished product warehouse (520m2) Storage.

The storage area 2 covers an area of approximately 7881m2 and is connected to the glass bottle production workshop and small capacity injection workshop. It mainly involves the packaging material warehouse (inner packaging 155m2, outer packaging material 619m2, glass bottle warehouse 1436m2), raw and auxiliary material constant temperature warehouse (464m2), raw and auxiliary material cool warehouse 65m2, and finished product room temperature warehouse (5142m2) of the production line.

The storage area three covers an area of approximately 2656m2 and is built within the module of the second workshop for traditional Chinese medicine extraction. It is equipped with a constant temperature warehouse (including traditional Chinese medicine material warehouse, net medicinal material warehouse, and traditional Chinese medicine decoction piece warehouse) and a cool warehouse (including traditional Chinese medicine material warehouse and net medicinal material warehouse).